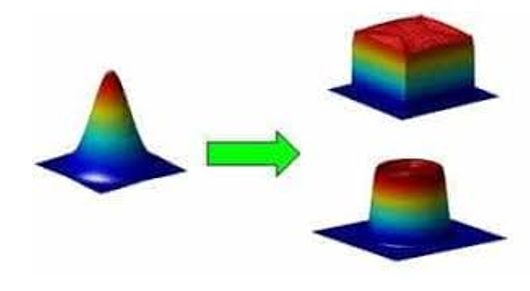

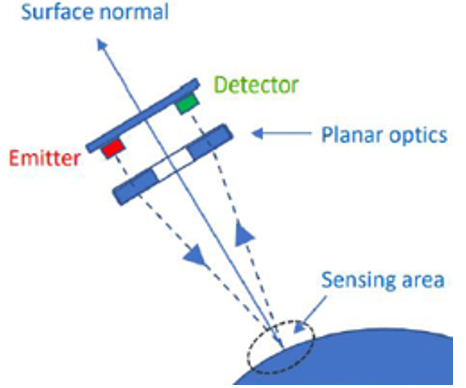

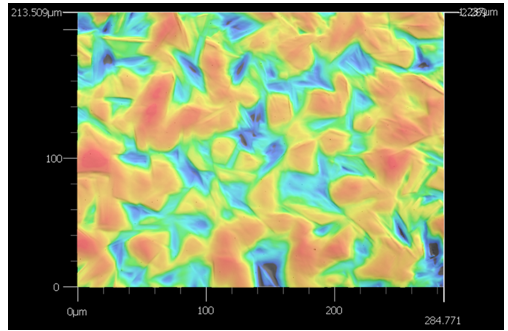

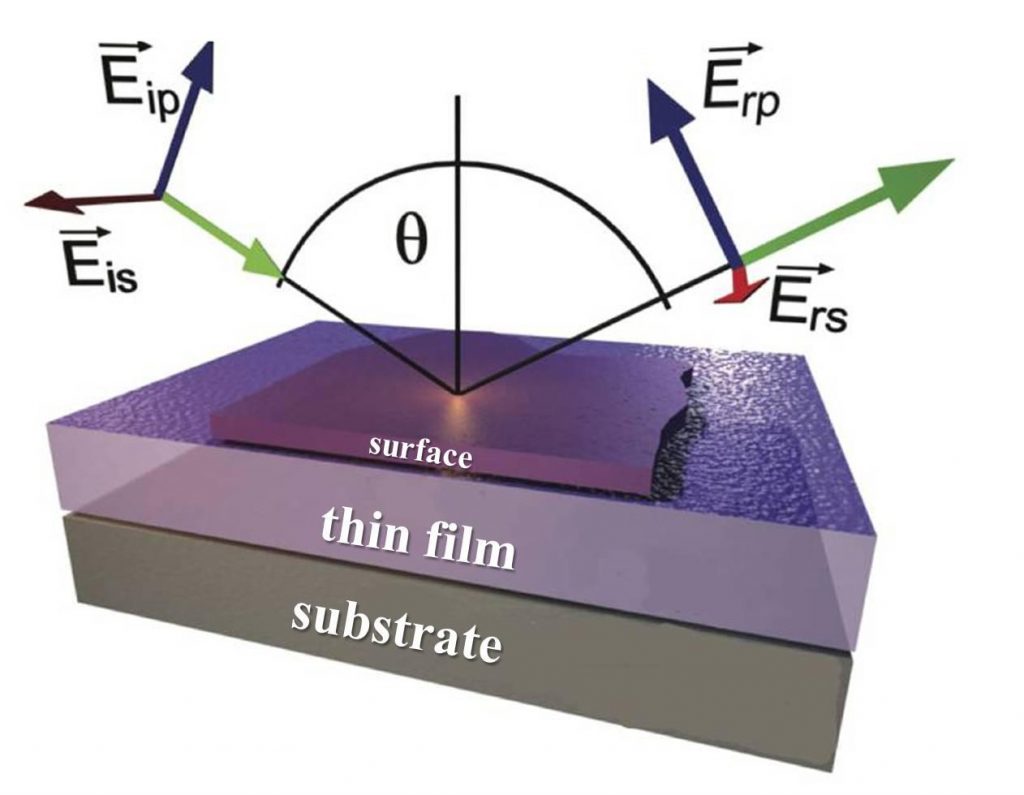

Meta-component example:

Spatially varying polarization

Reading time: 10 minutesWritten for: optical engineers, photonics engineers, researchers, technology scouts. Extra-relevant if you are interested in: meta-surfaces, spatially varying polarization (e.g. S-plate, Q-plate,